E27z Compact Excavator

Specifications & Options

E27z

Close/Open all PDF version

Operating weight with cab and bucket (ISO 6016)

2,705 kg

Transport mass (no attachment)

2,571 kg

Weight reduction with canopy

-118 kg

Additional weight for steel tracks

130 kg

Additional weight for long dipperstick

14 kg

Additional weight for heavy counterweight

91 kg

Ground pressure with rubber tracks

25 kPa

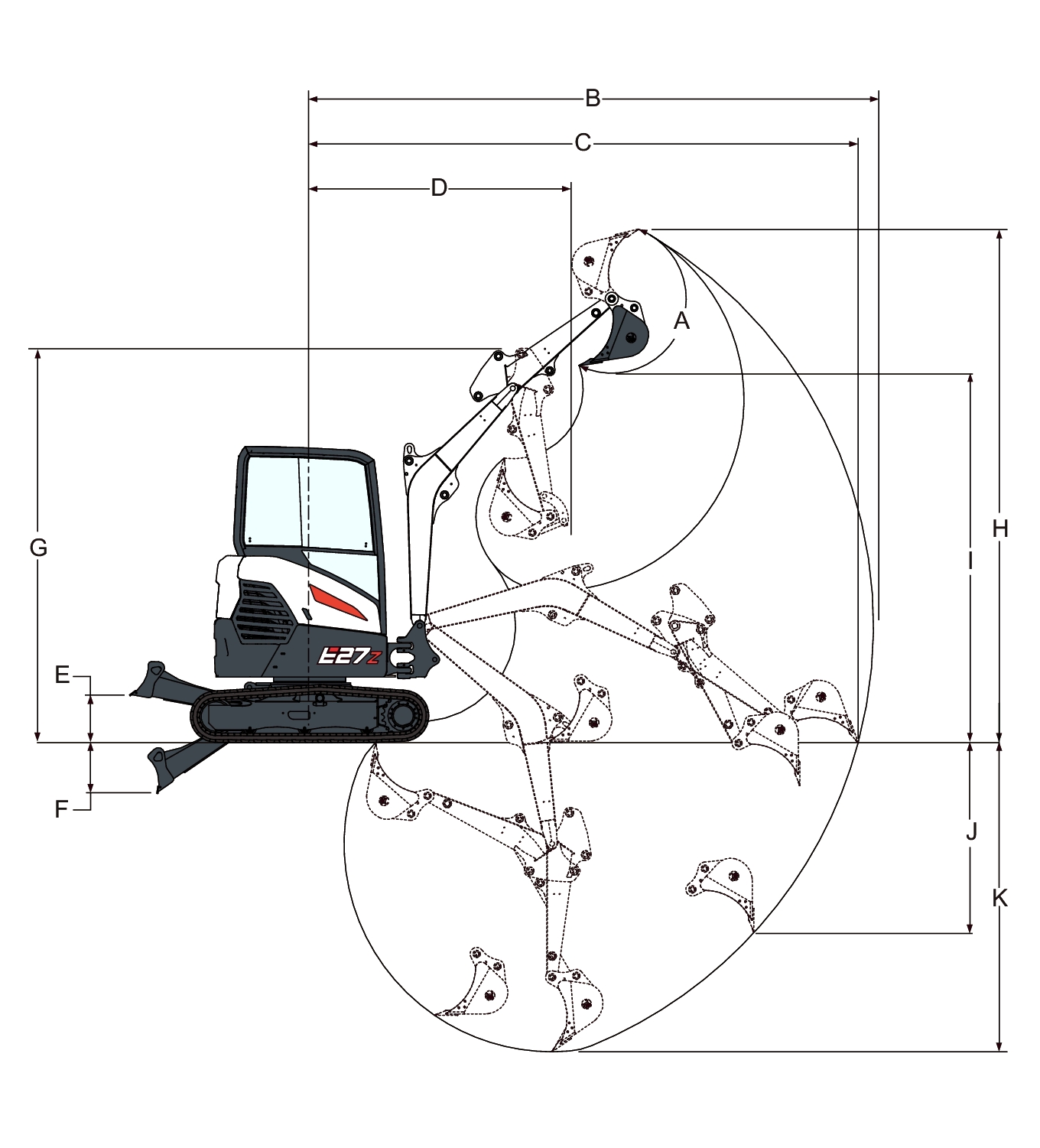

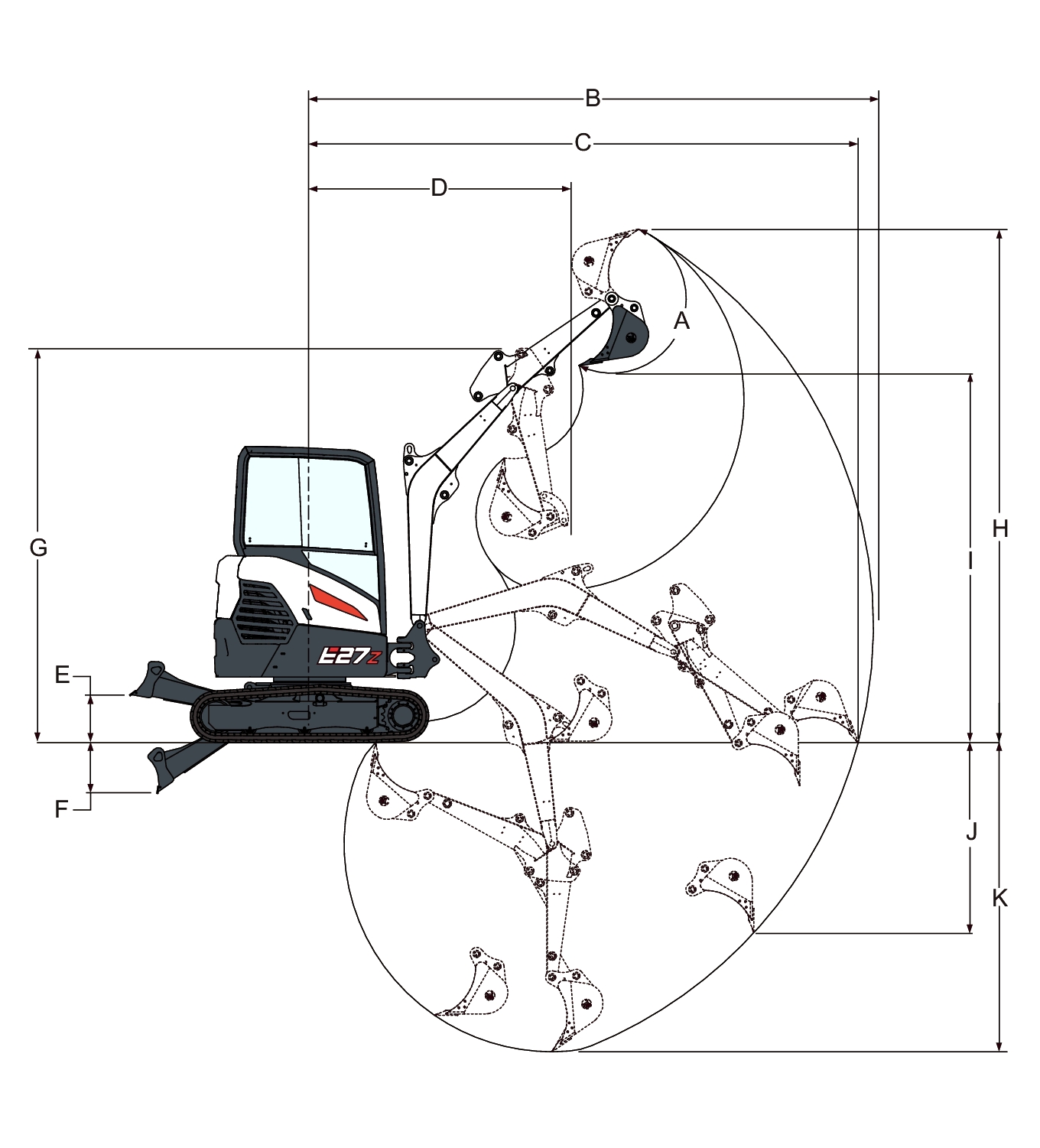

(A)

Bucket pivot angle

185 °

(B)

Maximum reach of working equipment

4,644 mm

(B*)

Maximum reach of working equipment, long dipperstick

4,931 mm

(C)

Maximum reach at ground level

4,518 mm

(C*)

Maximum reach at ground level, long dipperstick

4,814 mm

(D)

Maximum working equipment radius with boom at maximum height and dipperstick fully retracted

2,131 mm

(D*)

Maximum working equipment radius with boom at maximum height and dipperstick fully retracted, long dipperstick

2,135 mm

(E)

Maximum blade height

385 mm

(F)

Maximum blade depth

420 mm

(G)

Maximum height of working equipment with dipperstick retracted

3,247 mm

(H)

Maximum bucket tooth height

4,230 mm

(H*)

Maximum bucket tooth height, long dipperstick

4,430 mm

(I)

Maximum dump height

3,043 mm

(I*)

Maximum dump height, long dipperstick

3,243 mm

(J)

Maximum depth of vertical wall which can be excavated

1,567 mm

(J*)

Maximum depth of vertical wall which can be excavated, long dipperstick

1,818 mm

(K)

Maximum digging depth

2,547 mm

(K*)

Maximum digging depth, long dipperstick

2,847 mm

()

(* Dentoes values which long dipperstick installed)

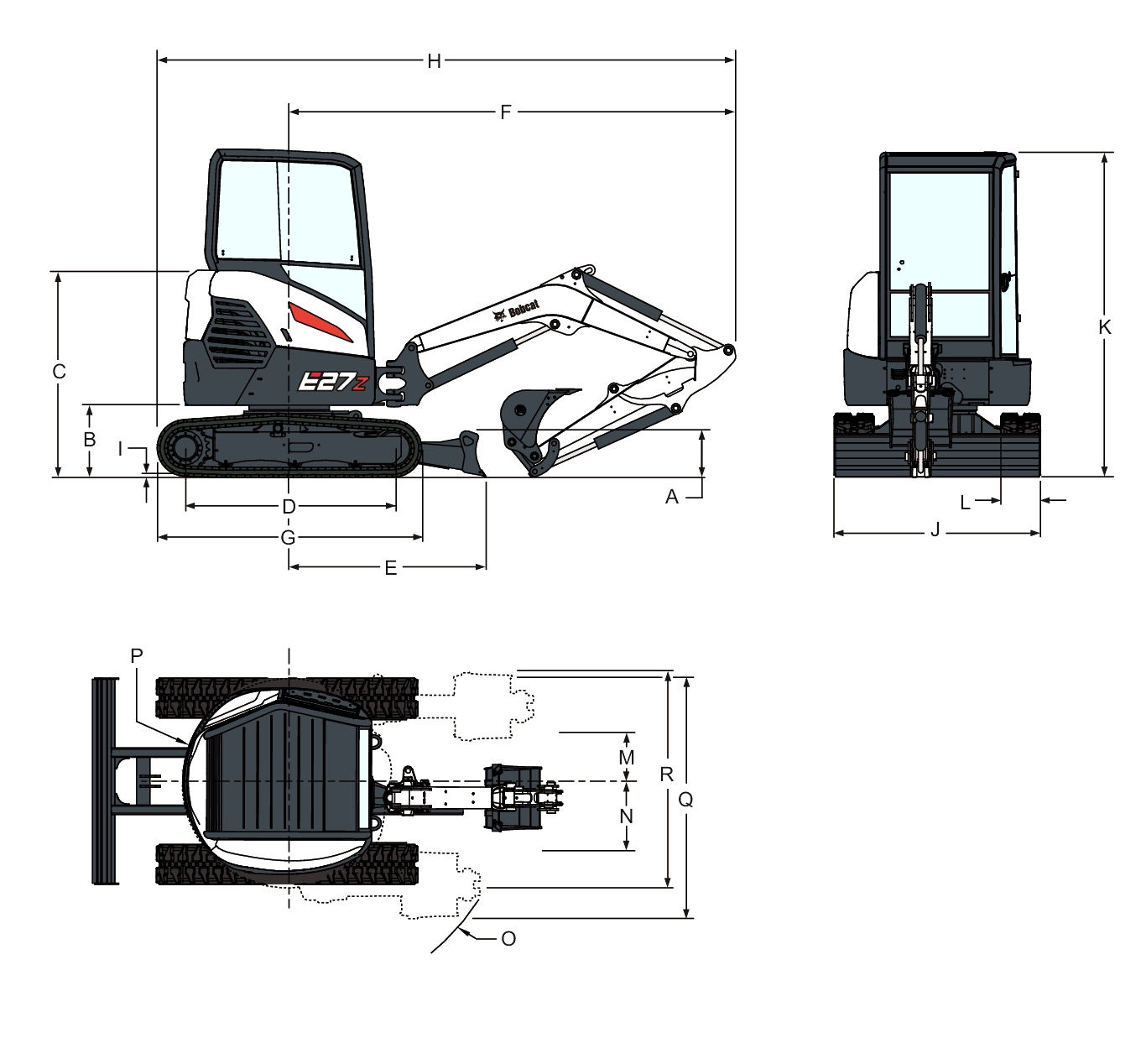

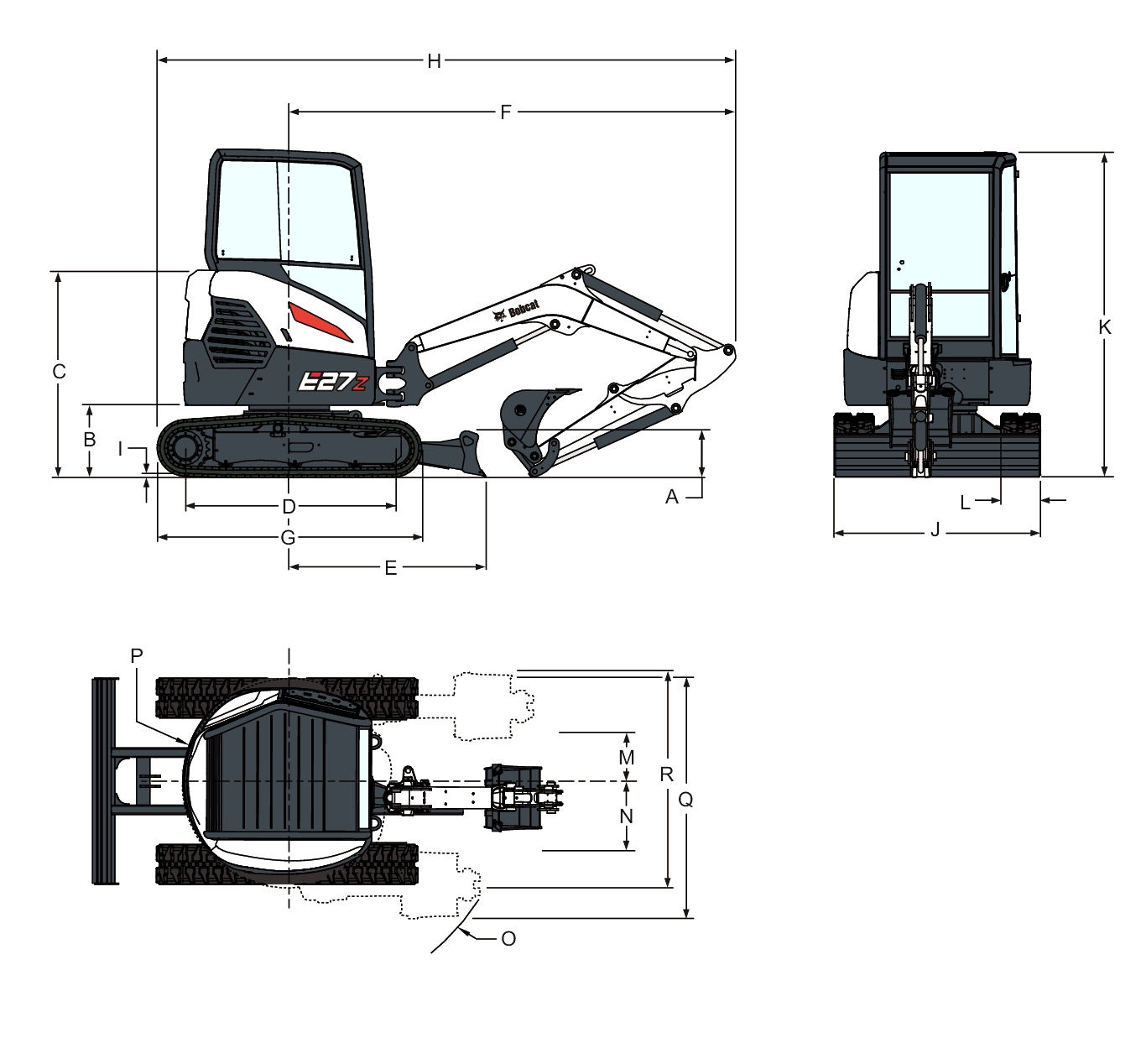

(A)

Blade height

319 mm

(B)

Clearance, upper structure to ground line

539 mm

(C)

Ground line to top of engine cover

1,540 mm

(D)

Length of track on ground

1,543 mm

(E)

Machine centre line to blade

1,462 mm

(F)

Minimum radius in travel position

3,343 mm

(G)

Overall length of track assembly

1,965 mm

(H)

Overall length in travel position

4,325 mm

(I)

Track lug height

21 mm

(J)

Blade width

1,550 mm

(K)

Height

2,438 mm

(L)

Track width

300 mm

(M)

Machine centre line to working equipment centre line, left-hand rotation

565 mm

(N)

Machine centre line to working equipment centre line, right-hand rotation

773 mm

(O)

Minimum turning radius

1,726 mm

(P)

Swing clearance, rear

785 mm

(Q)

Working width at maximum right-hand rotation

1,808 mm

(R)

Working width at maximum left-hand rotation

1,599 mm

Make / model

Yanmar / 3TNV76-PBC (Stage V)

Fuel

Diesel

Number of cylinders

3

Displacement

1,116 cm3

Maximum power @ 2400 rpm (ISO 14396)

14.9 kW

Maximum torque @ 1800 rpm (SAE J1995)

66.3 Nm

Pump type

Dual outlet variable displacement piston pump with gear pumps

Total hydraulic capacity

94.2 L/min

Piston pump capacity

67.5 L/min

Auxiliary (AUX1) flow

53.8 L/min

Auxiliary (AUX2) flow

20 L/min

Auxiliary (AUX1) relief

180 bar

Auxiliary (AUX2) relief

179 bar

Digging force, dipperstick (ISO 6015)

16,200 N

Digging force, long dipperstick (ISO 6015)

13,470 N

Digging force, bucket (ISO 6015)

23,720 N

Drawbar pull

29,023 N

Travel speed, low range

2.5 km/h

Travel speed, high range

4.3 km/h

Boom swing, left

70 °

Boom swing, right

55 °

Slew rate

9.3 RPM

Fuel reservoir

34.4 L

Hydraulic reservoir

10.2 L

Noise level LpA(EU Directive 2006/42/EC)

79 dB(A)

Noise level LWA(EU Directive 2000/14/EC)

93 dB(A)

Whole body vibration (ISO 2631–1)

0.2 ms-2

Hand-arm vibration (ISO 5349–1)

0.5 ms-2

- 1550 mm dozer blade

- 300 mm rubber tracks

- Adjustable double acting auxiliary hydraulic (AUX1) with Quick Couplers

- Battery disconnect switch

- Blade float feature

- Clamp ready

- Control console locks

- Cupholder

- Dual Direction Detent

- Engine/hydraulic monitor with shutdown

- Foldable and ergonomic travel pedals

- Full fuel warning alarm

- Horn

- Object handling package (Valves, OWD, Lifteye)

- Proportional fingertip auxiliary and boom swing offset hydraulic control

- Retractable seat belt

- Suspension seat with high back

- Storage compartment

- TOPS/ROPS/FOPS canopy * (1)

- Two-speed travel with Auto shift

- Upper structure four-point tie down

- Work light (boom)

- Water separator

- Warranty: 24 months, 2000 hours (whichever occurs first)

(1) Roll Over Protective Structure (ROPS) – Meets requirements of ISO 3471. Tip Over Protective Structure (TOPS) – Meets requirements of ISO 12117. Falling Object Protective Structure (FOPS) - Meets requirements of ISO 3449.

- Additional halogen lights

- A-SAC package (Tilt coupler lines, Dlx displ.)

- Auto idle

- AUX1 direct return to tank

- AUX1/AUX2/Drain on arm

- AUX2 hydraulics

- Beacon

- Bobcat hydr. pin grabber

- Bucket valves (AUX3) kit

- Case drain line kit

- Clamp w/ AUX1 valve

- Comfort package cab (Cloth susp. seat & Dlx displ.)

- Comfort package plus cab (Heated seat, Dlx displ.)

- Demolition kit (arm & bucket cylinder covers)

- Grease Gun Set (Gun + Holder in Machine)

- Heavy counterweight

- Hydr. coupler lines (AUX5)

- Keyless ignition

- L/R mirrors

- LED lights set

- Long dipperstick

- Object handling package (Valves, OWD, Lifteye)

- Radio FM/AM/DAB/Phone Ready

- Special application kit

- TOPS/ROPS/FOPS cab

- Travel motion alarm

Certain specification(s) are based on engineering calculations and are not actual measurements. Specification(s) are provided for comparison purposes only and are subject to change without notice. Specification(s) for your individual Bobcat equipment will vary based on normal variations in design, manufacturing, operating conditions, and other factors.